DOUBLE TWIN

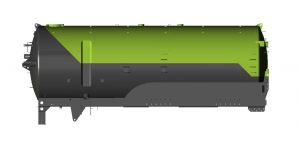

Often copied but never equaled is the KAWECO DOUBLE TWIN undercarriage. With over 15 year of experience, KAWECO is market leader in spreading slurry in a soil-friendly manner. DOUBLE TWIN means 4 tractor wheels in a row. The benefits are obvious: less damage to the soil while applicating and easy turning on the headland. The 4 large tractor wheels provide an enormous surface and lower tire pressure which means there is less pressure on the soil. Because the tires are relatively narrow, turning on the headland is easier, and narrow turns can be made without damaging the turf.

KAWECO DOUBLE TWIN, many tires make light work!

The DOUBLE TWIN undercarriage

The KAWECO DOUBLE TWIN undercarriage consists of 2 pendulum elements, both with 2 axle housings. The pendulum elements provide a perfect soil adjustment and ensure that the load is distributed evenly during transport. Integrating the DOUBLE TWIN undercarriage in the chassis of the tanker results in a compact and strong construction that in terms of weight, is equal of even lighter than our closest competitors.

Hitch construction

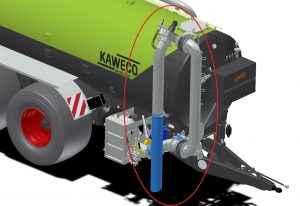

The entire DOUBLE TWIN series is equipped with the heavy KAWECO Premium linkage. The hitch is fully mounted to the chassis, so that there will be no traction on the tanker. The lifting cylinders are double-acting, which makes them adjustable both in terms of pressure and unloading, or fully pressureless. Thanks to the controls of the hitch at the back of the tanker (Optional) and the linkage hooks, mounting a slurry injector is very simple.

Pumps

All KAWECO DOUBLE TWIN tankers come with high-grade BP vacuum pumps by default. The standard pumps have a compressor capacity of 13,500 L/min. This capacity is achievable because of the rotor with 4 slanted rotor blades. The blades are cooled and lubricated by a drip oil pump. To further improve the cooling (keeping the capacity at the desired level) the pump is equipped with standard direct air injection. If the machine comes to a standstill, a special valve in the pump will preserve the vacuum.

If you work with a field edge container, for instance, and the pump is continuously running at full capacity, you can opt for a water-cooled vacuum pump. The cooling water will be pumped into a separate compartment of the tanker through a separate water pump.

Pumps and slurry piping at VC tankers

Advantages of the vacuum tank include: little wear and tear, low maintenance costs and low own weight. Disadvantages are: the dosage, the capacity during filling and unloading. Furthermore, during filling, the slurry is, as it were, pulled apart by the air displacement. As a result, the tank is never completely filled.

Operation

The functions of the tanker are operated by means of the tractor’s valves. To simplify the process, the hitch and the valve at the back of the tanker are combined by means of a sequential switching valve. If, however, multiple, very demanding functions are installed, the tanker is equipped with the KAWECO Comfort operating system. To operate the valves, the joystickbox can be used, which is easy to install in the tractor. For tankers with speed dependent dosage, the KAWECO Premium ISO-BUS operating system can be used. The tanker will then be operated by means of a joystick with 24 functions, and a 5,7″ Basic terminal with color display.

KAWECO DOUBLE TWIN OPTIONS

The PROFI II can be equipped with a suspended drawbar. This enhances the driving comfort. Especially when driving a lot on the road. The height of the tank can also be easily adjusted.

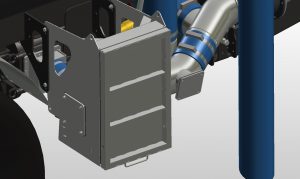

The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s). With a PTW model, a Stonecatcher with hydraulic cutting work is almost always mounted.

The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s). With a PTW model, a Stonecatcher with hydraulic cutting work is almost always mounted.

| • Filling arm right side |

| • Pivot point under controlled by a hydraulic cilinder |

| • Pivot point above controlled by a hydraulic cilinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

The KAWECO filling-arm saves you valuable time and makes filling easier.

| • Filling arm right side |

| • Pivot point under controlled by a hydraulic cilinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

The KAWECO suction arm saves you valuable time and makes filling easier. The PRO version is equipped with a hydraulic spindle motor for a larger swivelling range.

| • Required hydraulic volume: 45 l / min |

The maxi filler is recommended for thicker slurry or when the slurry has to be sucked out of a deeper cellar. The maxi filler also relieves the slurry pump, making it less vulnerable to wear and tear. In addition, the KAWECO maxi filler guarantees a faster loading process.

This guillotine valve ensures that the filling-arm leaks less.

| • CAT II / III on CAT II width 870 mm |

| • Max. lifting capacity 3.200 kg, arable land injector 3.000 kg |

| • Sequence linking single-acting lifting cylinder |

| • 1 x DA tractor valve for single acting hitch cilinder, valve and distributor (not reversible) |

| • 1 x DA tractor valve for folding in and out fertilizer |

• Control: 1 DA tractor can be used for 5 different functions. The Easy-Go is the easiest option for joystick control. When choosing a control system, it is important to consider how many functions the tanker needs. Up to 5 functions can be operated with an Easy-Go system. When a lot of oil is required or a applicator needs to be controlled, you can choose for a Load-Sensing control.

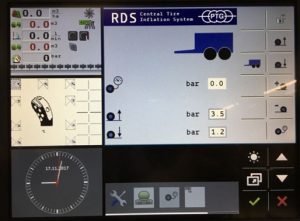

| • KAWECO multifunctional joystick with 24 functions |

| • KAWECO BASIC Terminal |

| • Operation of automatic dosage control |

The KAWECO ISO-BUS control is a Load-Sensing control system with which all tank functions can be controlled. The system also directly takes care of the oil quantity. A target value is entered after which the application rate is regulated by the By-Pass valve. The amount of slurry that goes to the injector is measured with a flow meter.

KAWECO DOUBLE TWIN tires

Do you have a question?

Fill in your details and we will contact you as soon as possible.

When you use this form, you agree to the storage and processing of your data through this website. Data protection