PROFI III-Serie Slurrytanker

The KAWECO Profi III tanker series offer you a large variety of complete and professional tanks for contractors and farmers. Typical for the PROFI III tankers is the sturdy, independent and twist-lock mounted chassis. This unique construction guarantees that the traction of the tractor gets transmitted to the applicator by the chassis only. This means that the tanker is only used to transport the slurry, and that the chassis is ultra-stable. All PROFI III tankers are equipped with a flow meter with speed-independent dosage through By-Pass regulation. The dosing and all other hydraulic functions are controlled by the KAWECO PREMIUM ISO-BUS on-board computer. In addition, the PROFI III is equipped as standard with a heavy KAWECO LIFTMAX PRO hitch and a Maxi Cut Stone catcher.

The PROFI III is equipped for heavy-duty work!

Specifications

| Net contents [L]: | Tandem: 16,300, 18,500, 20,260, 23,200 Tridem 23,000, 25,000, 28.000, 30,000, 32,000 |

|---|---|

| Undercarriage: | Hydraulic pendulum suspension, come with 2 large accumulators for optimum suspension when empty and full |

| Steering system: | Tandem up to 20,000 = hydraulic forced steering by hydraulic cylinder on the left-hand side of the drawbar. Tandem 23,200 = Forced steering through mobile Elektronik control system. Tridem = up to 25,000 front and rear axle hydraulic forced steering. Tridem From 28,000 = hydraulic forced steering through mobile Elektronik control system. |

| Axle base [mm]: | 1.810 |

Undercarriage and tanker construction

Not just the weight of the applicator but also the distance behind the tanker determines how heavy the burden on the chassis will be. With more than 50 years of experience in manufacturing and engineering, KAWECO knows how to solve these aspects. The chassis of a PROFI III tanker is the only one who’s specially constructed to transfer the lifting-power to the tractor. Because of the six twist locks the tanker is mounted to the chassis tension free. Whether the chassis undergoes traction or pressure forces, the tanker is mainly used for carrying the slurry. This is why the tanker can have a lighter construction, which will benefit the total weight of the machine.

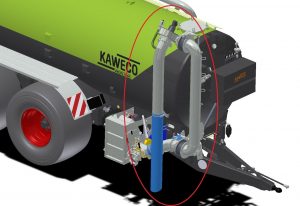

Hitch

All tankers from the PROFI III series are equipped with the heavy KAWECO Premium hitch. The hitch is fully mounted to the chassis so that there will be no force on the tanker. The lifting cylinders are adjustable in terms of pressuring and relieving pressure. Thanks to the standard control of the hitch at the back of the tanker and the link hooks to the lift bars, the attaching of an applicator is very simple.

Undercarriage

All PROFI III tankers are equipped with a hydraulic axle suspension and a load-independent suspension system. This suspension system has two large spring accumulators that always ensure optimum suspension, whatever the weight of the machine. As an option, the front axle can relieved of pressure, both in tandems and three-axle machines. If load is taken off the axle, the other axles can never be overloaded. All PROFI III tandem tankers have hydraulic forced steering of the rear axle and the PROFI III tridem tankers are steered on the front and the rear axle (all three axles optional). The hydraulic forced steering is controlled via a cylinder on the drawbar or, as an option, via an electronic potentiometer and the standard Load sensing hydraulics.

Pump and slurry piping PTW tanker

Advantages of the PTW-tanker are: precise dosing and high filling capacity. The filling of the tank remains guaranteed, regardless of the thickness of the slurry. In addition, the filling capacity is better maintained with greater suction depth. Possible limitations of the PTW-tanker are: relatively high maintenance costs and more wear and tear. The weight of the machine is also increased by the required piping.

Filling

Unloading

Previous

Next

Slurry route and stonecatcher

Every tank of slurry that is transported or unloaded will have to be filled first. Throughout the entire process, the filling capacity mostly depends on the slurry route and on the position of the pump, the pipes and the stonecatcher. The position of a KAWECO pump is always central. In the middle, underneath the tanker. This results in the shortest possible slurry route with fewer unnecessary bends and a central distribution of the weight. With an adjustment of the pipes you can work with maximal capacity if wanted. KAWECO always uses 8″ pipes to the suction side and maximum two times 6″ to the pressure side. If the pump capacity is increased, the pipes will be larger too. Therefore, a 9,000 l/min pump always comes with a 10″ filling piping and two 8″ pipes on the pressure side. The tank gets filled by the double pipes at the pressure side because of the automatic opening of the By-Pass.

Pumps and filling arms

To unburden the driver, KAWECO offers a broad selection of filling arms for the PROFI III series. Every filling arm is preferably placed on the right-hand side of the tanker to create the shortest possible slurry route. In addition to a side filling-arm, KAWECO also provide many crane of swivel arm options. In most cases, KAWECO advises to mount a maxifiller to be able to use the highest capacity possible. This maxifiller contains a hydraulic driven vane wheel that presses the slurry into the suction pipe, which decreases the negative pressure at the pump side. The extra pump support offers many benefits. For example: the negative pressure is strongly reduced, meaning that the pump does not have to suck up the slurry as intensely. This will improve the machine’s lifespan, because parts that will wear, i.e. bearings, rotor and seals, will not be used as intensely.

Touch 800

Joystick

Joystick PRO

Previous

Next

KAWECO ISO-BUS control

All PROFI III tankers are operated via KAWECO premium control. This control terminal offers many, conveniently arranged options. All systems are equipped with a multifunctional joystick with 24 functions and a 5,7″ Basic Terminal. As an option, we offer an 8″ or an 11″ Touch Terminal, and the PRO joystick.

Weighing and sampling

Thanks to the unique, independent construction of the chassis and tanker all PROFI III tankers can be equipped with a weighing and sampling cabinet. The robust weighing cells are placed in between the chassis and the tanker, using a special assembly process. This way, the height of the tanker and the construction method of the slurry route will not be influenced.

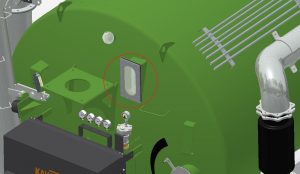

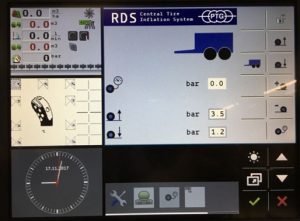

Tyres, wheels and soil pressure

Thanks to the unique construction method the KAWECO PROFI III tankers are very soil-friendly. If so desired, you can opt for a tyre with a 1,800 mm diameter and a width of 800 mm (optionally up to 900 mm). These tyres ensure a larger ‘footprint’, which means the soil won’t be pressured much. To be able to make optimum use of these types, your KAWECO PROFI III can be fitted out with a tire inflation system. This system can be combined with the control computer to simplify operations.

Options for Profi III

Despite the very complete standard set-up of the Profi III tankers there are many options for equipping your KAWECO PROFI III as you like it. Think about traction-increasing options like a Top pressure cylinder or a two-compartment system. See the most common options below.

KAWECO PROFI III standard equipment

• Frontside left with automatic switching from filling to circulating and potmeter for exact tank content. Because of the automatic turn-off, the tank cannot be over pumped, but automatically switches from filling to circulating. The potentiometer within the filler gauge ensures an exact determination of the tank content.

The heavy-duty KAWECO LIFTMAX PRO is prepared for heavy-duty work. Heavy-duty injectors as well as wide dragging feet/hose applicators can be mounted in this hitch. The maximum width of the applicator depends on the contents and therefore the length of the tank.

| > Fixed lower links CAT III (width of 1,010mm) |

| > Mechanical adjustable toplink CAT III |

| > Double working lifting cylinder with ground pressure regulation system |

| > Lifting cylinder with damping |

| > Maximum lifting capacity 4.000 kg (depending on tank and injector version) |

| > 2 buttons on rear side of the tanker to lower or to lift the hitch |

| > 7-pin plug for lighting of applicator |

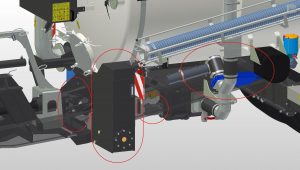

The PROFI III is standard equipped with the most complete cutting cleaner (KAWECO Maxi Cut Premium). This to prevent the pump or distributors of the applicator from being damaged by objects in the slurry. Heavy parts remain at the bottom of the stonecatcher, and smaller parts are cut by the hydraulic cutting head with 3 blades.

| • KAWECO Maxi Cut Premium 8″ | |

|

• Hydraulic axle suspension.

The PROFI III is equipped with hydraulic axle suspension as standard. This makes the PROFI III comfortable on the road and in the field. In addition, it ensures a good drawbar pressure when working with heavy fertilizers. Optionally, the PROFI III can be equipped with a lift axle (three-axle) or axle relief.)

By using ISOBUS, tractors are easily connected to implements. The KAWECO ISOBUS Control makes it possible to operate the tank through the terminal of the tractor. It is also possible to use the function keys of the tractor. The tanker can also communicate with the GPS-system of the tractor, which makes it possible to close off sections. When speed-dependent dosage is required, the KAWECO ISOBUS Control should be chosen. The position of the By-Pass or the number of rotations of the slurry pump is automatically controlled on the basis of the speed and the entered target value. The KAWECO multi-functional control lever and the KAWECO Basic Terminal are standard supplied. All functions of the slurrytank can be operated via this terminal and in addition 24 functions can be assigned to the joystick. All this results in easy operation and comfortable working!

| KAWECO ISOBUS Control including: | |||

|

KAWECO PROFI III options

Every KAWECO tank is standard equipped with a high-quality treatment. The inside is fitted with a two-component EPOXY resin. The outside is scoped and sprayed with two-component polyurethane lacquer. The standard color is KAWECO white with orange.

Two RAL colors are available as an option.

This treatment is many times more durable than a zinc layer and will retain its color even after years.

The KAWECO top pressure cylinder is designed for extra driving comfort and optimum weight distribution. The cylinder can push as well as pull and can be steplessly adjusted via the ISO-BUS. This allows extra pressure to be applied to the front axle of the tractor on the road or in the field for optimum weight distribution.

| • 10″ stonecatcher with integrated hydr. driven cutter |

| • Required hydraulic volume: 25 l / min |

| • Only possible with 9.000 l/min pump |

| • For docking station located at the ground (slide valve mounted at stonecatcher) |

| • First pivot point controlled by a hydraulic cylinder |

| • Std. With slide valve and vent valve mounted at the end of the arm |

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic cylinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

| • One pivot point, actuated by a hydraulic cylinder |

| • Std. 8″ Maxi Filler |

| • Std. 8″ slide under the Maxi filler |

| • Mirrors mounted on the left and right of the front unit for road safety |

| • Std. Lighting for front unit |

| • Required hydraulic volume: 45 l / min |

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

KAWECO PROFI III Tires

Do you have a question about the PROFI III?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy