PRESS RELEASE

Hengelo (Gld), November 1, 2019

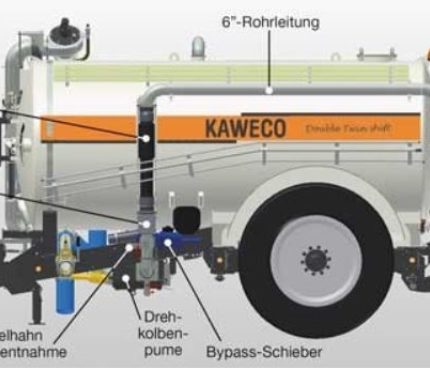

REESINK PRODUCTION INTRODUCES KAWECO WHEEL LOADER ON THE AGRITECHNICA

At the beginning of 2019, Reesink Production took over the business activities of the wheel loader brand QUAPPEN. The QUAPPEN brand offers a complete product range with wheel loaders in the weight class from 2 to 3.8 tonnes. The wheel loaders are available in various versions suitable for the agricultural sector, infrastructure and landscape maintenance.

The originally German wheel loaders have been produced in the Netherlands since 2011 by Q-Load BV, of which more than 500-wheel loaders are now in circulation. At the beginning of 2019, Reesink Production started the production of QUAPPEN wheel loaders in Hengelo (Gld). From the 1st of November 2019 on, the wheel loaders will be sold under the KAWECO brand name. The original orange, grey colour scheme from KAWECO was chosen for this.

For the KAWECO dealers, this means a nice addition to the extensive product range. For the distribution of the wheel loader, in first instance the existing dealer network will be used.

For Royal Reesink as a leading distributor of equipment in agriculture, earthmoving and landscape maintenance, the KAWECO wheel loaders are an interesting addition. For Reesink Production as a manufacturer, this product has a less seasonal decline, which has advantages in addition to the production of slurry and silage technique.

Due to increasing market demand, Q-Load BV searched for a takeover candidate and found it in Royal Reesink BV. Reinier Hulst (former director/ owner) will continue to support the KAWECO team in 2019 to ensure the smoothest possible transition.

The KAWECO/ QUAPPEN team is happy to help you at the Agritechnica, stand A48 hall 6.

For further information: www.kaweco.com and www.reesinkproduction.nl

For further information you can contact the KAWECO sales team.

Tel.: + 31- (0) 88 134 2900/ info@kaweco.com