DOUBLE TWIN SHIFT Slurrytankers

The DOUBLE TWIN SHIFT slurry tanker is the most professional way of injecting slurry. The DOUBLE TWIN SHIFT slurry tankers make themselves indispensable thanks to their enormous volume, big filling capacity, maneuverability, and their well-developed undercarriage. With a volume of 12.000, 14,000 or 16,000 liters, KAWECO manufactures the largest single-axle tanker available in the market. Thanks to the undercarriage the soil pressure can be kept very low, despite the large volume of the tanker. KAWECO is the inventor of the DOUBLE TWIN SHIFT undercarriage which has 4 large tractor wheels in a single row. This gives the tanker the maneuverability of a single-axle slurry tanker, while it has the load capacity of a tandem axle tanker. This unique undercarriage means that you can inject with a significantly lower soil pressure than a self-propelled machine. This means you can start your work earlier in the year, and continue for a longer period than a self-propelled machine, even in bad weather. Another major benefit of the DOUBLE TWIN SHIFT is that your tractor can also be used for other activities, compared to a self-propelled machine, which is not operational for at least 6 months a year. KAWECO DOUBLE TWIN, many wheels make light work!

The DOUBLE TWIN SHIFT undercarriage

The KAWECO DOUBLE TWIN SHIFT undercarriage has four large wheels in a single row. The outer wheels can be shifted outwards. This creates an even track of the tanker and the tractor without driving over the same track multiple times. Thanks to this unique construction the soil life suffers minimum, and the drainage of the soil is kept optimal. This results in fewer puddles in the field, no tracks, being able to start injecting sooner in the year etc. The stable, extendible profiles are provided with synthetic sliding strips, which makes the system very user-friendly. The wheels have hydraulic suspension, which provides the perfect fit with the contours of the field, as well as a balanced distribution of the weight divided over the 4 wheels. On the road, the hydraulic suspension provides comfortable and stable driving properties. All wheels are Air-braked for maximum safety.

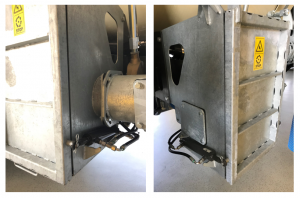

Slurry route and stonecatcher

Every tanker of slurry needs to be filled before spreading. Throughout the entire process, the filling capacity mostly depends on the slurry route, i.e. on the position of the pump, the pipes and the stonecatcher. The KAWECO pump is always placed in a central position of the machine, centralized underneath the tanker. This results in the shortest possible slurry route with fewer unnecessary bends and a better distribution of the weight. If you wish to use the maximum pump capacity, the pipes need to be adjusted. This means that we always use 8″ pipes to the suction side and maximum two 6″ to the pressure side. If the pump capacity increases the pipes will adjust with it. This means that a 9.000 l/min pump comes with 10″ suction pipes and 8″ pressing pipes.

Pumps and slurry piping with PTW tankers

Advantages of the PTW-tanker are: precise dosing and high filling capacity. The filling of the tank remains guaranteed, regardless of the thickness of the slurry. In addition, the filling capacity is better maintained with greater suction depth. Possible limitations of the PTW-tanker are: relatively high maintenance costs and more wear and tear. The weight of the machine is also increased by the required piping.

Hitch

All tankers from the DOUBLE TWIN SHIFT series are equipped with the heavy KAWECO Premium hitch. The hitch is fully mounted to the chassis, so that there will be no force on the tanker. The lifting cylinders are double-acting, which makes them adjustable both in terms of pressure and unloading, or even fully pressureless. Thanks to the standard operation of the hitch at the back of the tanker and the link hooks to the linkage, the mounting of an injector is very simple.

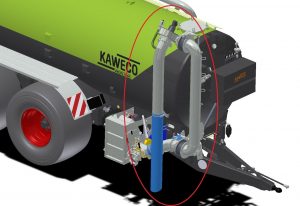

Pumps and filling arms

To unburden the driver, KAWECO offers a broad selection of filling arms for the DOUBLE TWIN Shift. Each filling arm is preferably placed to the right-hand side of the tanker, to create the shortest possible slurry route. In addition to the standard 8″ filling arm, with cylinder-operated pivot points, KAWECO also offers many crane and swivel arm options. A valve is mounted to vent the filling arm as soon as possible after the tanker has been filled. The slurry will flow back into the pit, with hardly any spilling. In most cases, KAWECO advises to install a maxifiller to be able to use maximum pump capacity. This maxifiller consists of a hydraulic driven vane wheel that presses the slurry into the suction pipe, which decreases the negative pressure on the pump side. The extra pump support offers many benefits that can be earned back fast. For example, the negative pressure is strongly reduced, meaning that the pump does not have to suck up the slurry as intensely. This will improve the machine’s lifespan, because parts that will wear, i.e. bearings, rotor and seals will not be used as intensely.

Slurry dosage

To guarantee perfect dosage, all DOUBLE TWIN SHIFT tankers are equipped with a BY-PASS dosing system. This system guarantees perfect dosing, by working with a flow meter. An upright pipe measures the amount of slurry pumped to the applicator. If this isn’t the right amount, the BY-PASS valve on the other side of the underlying Y-piece opens or closes. The position of this dosing valve is visible in the computer as a percentage. During the turning on the headland, the 3-way valve at the back of the tanker switches. When the next run has begun, the applicator can be filled with slurry straight away, meaning that slurry will flow from the outlets straight away. During the filling of the tank the dosing valve opens fully, meaning that at the pressing side of the pump an extension takes place to two 6″ pipes. This lowers the resistance on the pressing side, which increases the filling capacity.

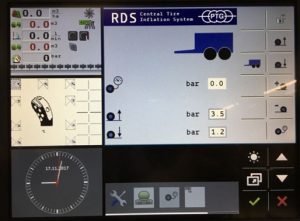

KAWECO ISO-BUS controls

All DOUBLE TWIN SHIFT tankers are operated via KAWECO premium control. This control terminal offers many, conveniently arranged options. All panels are equipped with a multifunctional joystick with 24 functions and a 5,7″ Basic Terminal. As an option, we offer an 8″ or an 11″ Touch Terminal, and the PRO joystick.

KAWECO DOUBLE TWIN SHIFT options

Every KAWECO slurry tanker is standard equipped with a high-quality treatment. The inside is fitted with a two-component EPOXY resin. The outside is scoped and sprayed with two-component polyurethane lacquer. The standard color is KAWECO white with orange.

Two RAL colors are available as an option.

This treatment is many times more durable than a zinc layer and will retain its color even after years.

The KAWECO top pressure cylinder is designed for extra driving comfort and optimum weight distribution. The cylinder can push as well as pull and can be steplessly adjusted via the ISO-BUS. This allows extra pressure to be applied to the front axle of the tractor on the road or in the field for optimum weight distribution.

| • 10″ stonecatcher with integrated hydr. driven cutter |

| • Required hydraulic volume: 25 l / min |

| • Only possible with 9.000 l/min pump |

A larger pump of 9,000l/min also requires a larger flow of slurry. For maximum capacity, KAWECO builds the complete suction side out of 10″ pipes starting from a 9,000 l/min pump. Also the discharge side is increased from 6″ to 8″ pipes.

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic cylinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

The KAWECO filling-arm saves you valuable time and makes filling easier. Optionally, the filling arm can be equipped with a maxi-filler for optimum capacity.

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

The KAWECO suction arm saves you valuable time and makes filling easier. The PRO version is equipped with a hydraulic spindle motor for a larger swiveling range. Optionally, the filling arm can be equipped with a maxi-filler for optimum capacity.

| • One pivot point, actuated by a hydraulic cylinder |

| • Std. 8″ Maxi Filler |

| • Std. 8″ slide under the Maxi filler |

| • Mirrors mounted on the left and right of the front unit for road safety |

| • Std. Lighting for front unit |

With the KAWECO FRONT-UNIT it is easy to dock to a nursetank. With the arm in front of the cabin you have perfect visibility. Also, the applicatorboom can always be folded out because you don’t have to stand sideways along the nursetank.

| • Required hydraulic volume: 45 l / min |

The maxi filler is recommended for thicker slurry or when the slurry has to be sucked out of a deeper cellar. The maxi filler also relieves the slurry pump, making it less vulnerable to wear and tear. In addition, the KAWECO maxi filler guarantees a faster loading process.

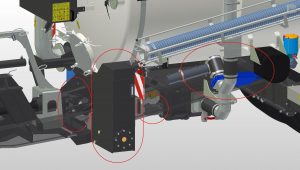

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

The Hydro Dynamic makes it possible to spread slurry with completely variable rates. The dosage is regulated by the rotations of the slurry pump. With this system, the application rate can be quickly adjusted when, for example, working with a section-control.

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

The Hydro Dynamic makes it possible to spread slurry with completely variable rates. The dosage is regulated by the rotations of the slurry pump. With this system, the application rate can be quickly adjusted when, for example, working with a section-control.

KAWECO DOUBLE TWIN SHIFT Tires

Do you have a question about the Double Twin Shift?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy