PROFI CARGO VC

PROFI CARGO Series

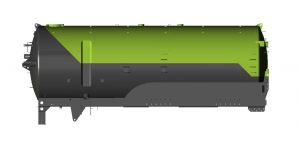

The KAWECO PROFI CARGO tank is distinguished by its light but stable construction. The CARGO slurry tank is extremely suitable for transporting slurry, both on the road and in the field. The modular construction makes it easy to adapt the tank to your needs.

Specifications

| Net content [L] : | 26.150 |

|---|---|

| Undercarriage : | Parabolic suspension |

| Steering: | Trailed-steered rear axle |

Optimally equipped for transport

The PROFI GARCO VC is available in 26m3. This tank has been specially developed for slurry transport. The CARGO is equipped with a high quality Battioni Pagani Ballast vacuum pump. The tank is available with several specific options to make the transport of manure as efficient as possible.

Tanker and chassis

KAWECO produces high-quality products with high reliability and optimum efficiency. When it comes to the PROFI CARGO series, this is reflected in the low center of gravity achieved by an integrated chassis with parabolic suspension. The 1st axle is equipped with a turntable, thus guaranteeing a comfortable ride. The integrated chassis provides a low and stable tank, which is specially designed for use in sloping terrain and mountainous landscapes.

Drawbar

The drawbar of the PROFI CARGO tanks is built with a simple and robust construction. The front axle is placed behind the turntable, which automatically creates a good weight distribution.

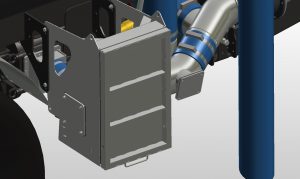

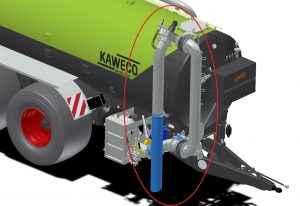

Pump and slurry piping VC tanker

All PROFI CARGO vacuum tanks are equipped as standard with very high quality BP vacuum pumps. The standard pumps have a compressor capacity of no less than 13,500 L/min. This capacity is realized by a rotor with 4 inclined rotor blades. The blades are cooled and lubricated by an oil drip pump. In order to further improve the cooling and to keep the capacity at the same level during the work, the pumps are standard equipped with direct air injection. When the pump is at a standstill, a special valve ensures that the vacuum is maintained.

Click here for a video of the Battioni Pagani Ballast pumps.

Do you have a question?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy

Photo album

XERION SADDLE TRAC tanker

XERION SADDLE TRAC tanker

Since the introduction of the CLAAS XERION in 1993, KAWECO has been a slurry technology partner. The first XERIONs were equipped with a KAWECO tanker with front- unit and successfully used as self-propeled applicator. After the introduction of the XERION 3300, KAWECO started to focus on the production of gooseneck tankers for the XERION TRAC VC. In both the Netherlands, England and Germany, the gooseneck tank is a well-known concept.

Since the introduction of the DOUBLE TWIN SHIFT gooseneck, the production number has more than doubled. To complete the full XERION range, at the end of 2015 KAWECO developed its own poly-tanker for the XERION 4000 SADDLE TRAC. In order to save weight, the tank is constructed entirely of epoxy resin. This method of construction reduces the weight by 1,500 kg, allowing the effective capacity to be increased. In combination with a 9.000 l/min pump and a very well thought-out slurry route, KAWECO offers a self-propelled tanker with an extremely high capacity.

Maximum filling capacity

The 16,000-l tanker is equipped with 10” piping and in combination with the Vogelsang VX186-520QD 12.000 l/min rotary lobe pump (Optional) the tanker can be filled within 80 seconds.

A few important characteristics:

– Complete piping from the filling arm up to the rotary lobe pump is 10” with a minimum number of bends. This is made possible thanks to a smart positioning of the pump. This also allows for the easy removal of the pump for maintenance using a pallet fork.

– The 10” maxi-filler in the filling arm of the front unit ensures that the slurry is pressed towards the pump. The positive result of this is increased capacity, smooth operation and longer life of the rotary lobe pump thanks to the lower negative pressure.

Stonecatcher

During filling, a stonecatcher with a capacity of 460L and an integrated cutting system ensures that stones are caught and that residual matter like hay and straw are shredded. This allows the slurry to flow through the pump and the distributor(s) effortlessly. The stone trap can be emptied hydraulically from the tractor cabin.

Maximum capacity

On the discharge side of the pump the 8” 3-way valve switches between circulating in the tanker and spreading. At the headland, the slurry is automatically circulated and is therefore immediately available again for the set application rate. During slurry application, the filling arm on the front unit is placed almost entirely behind a cabin column for optimal visibility. This also gives an almost 100% view of the filling arm during filling. The filling arm can swivel 135º and has a pivot point both on top and at the bottom of the arm.

GFK tanker construction

The tanker is made from glass fiber reinforced plastic. This light, yet extremely strong construction allows for a tanker content of 16,000 l. A filling stop makes it possible to fill the tanker up to a pre-set value. The tank is relatively slim so that there is always a good view to the rear. The KAWECO XERION build-on tank is equipped as standard with 4 LED work lights and a beacon.

Perfect interaction between tanker and XERION

The Vogelsang rotary lobe pump is driven by the power hydraulics of the XERION. The KAWECO computer communicates directly with the CEBIS computer of the XERION and thus ensures an accurate and rapidly responding automatic dispersion. Thanks to the stepless hydraulic drive, it is possible to fill the tanker with minimum motor revs. During spreading, the motor revs can be adjusted to the required power. The result is a lower diesel consumption.

With the KAWECO operating system the main functions of the KAWECO-tanker construction (to be determined by the user) can be operated by means of the multifunctional gear lever from the XERION. The other functions are operated via the Müller terminal or the joystick with 24 functions.

Important benefits of the CLAAS XERION 4000 SADDLE TRAC

– Low soil pressure thanks to crab-steering with 900 mm-wide tires

– Rotatable hydraulic hitch for crab steer. Cat. III with 5.5 tons lifting capacity.

– 462 hp (340 kW) engine power – Stage V

– Tires up to 900/60R42 possible (diameter 2.15 meters)

– Powerful and efficient ZF Eccom stepless transmission

– A reliable CLAAS/KAWECO dealer network for optimum onsite support

Do you have a question about the SADDLE TRAC tanker?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy

Photo album

Options for KAWECO slurry tankers

Available options for KAWECO slurry tankers

Two-compartment system

Filling opening on top of tanker with a hydraulic slide

Top pressure cylinder

KAWECO Maxi Cut Stonecatcher

Additional 3-way valve for pumping

KAWECO Docking arm

KAWECO filling arm

Unloading via slurry arm

KAWECO ROTA-arm

KAWECO TELE-arm

KAWECO Overhead crane arm

KAWECO Maxifiller

Front axle can be extended by 750mm

Mobil Electronic electric-hydraulic steering system

Axle lift front axle

Automatic lubrication

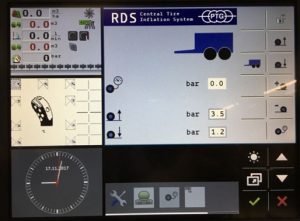

PTG tire inflation system

KAWECO Hydro Dynamic

KAWECO Hydro Dynamic DUAL

| • The extra LS pump controls a separate Bucher block with three sections, which controls the cutting cleaner, maxi filler and distributor. |

| • Larger oil tank, larger return filter and a separate filter for the leakage connection. |

| • Lower engine speed when filling, less oil needed from the tractor. |

Do you have a question?

Fill in your details and we will contact you as soon as possible.

View machine-specific options on the product pages:

NIR-sensor

NIR-sensor

What does the NIR-SENSOR measure?

What does the NIR-SENSOR offer you?

GPS options

Datamanagement

Do you have a question?

Vul uw gegevens in en we nemen z.s.m. contact met u op.

Photo album

KAWECO operating systems

KAWECO operating systems

There are three operating systems for the KAWECO tankers you can choose from. Based on KAWECO’s vast experience, the basic setting of each option is often sufficient. However, the setting can be adjusted to the client’s wishes, so that the high level of operating comfort is always guaranteed. When choosing an operating system it is important to look at future wants and needs.

KAWECO Easy-Go

When there is a demand for operating several functions, the Easy-Go offers a solution. With the KAWECO Easy-Go you can operate up to 5 tank functions with one double acting valve without the use of Load-Sensing.

This control can be used on a KAWECO PROFI I, PROFI II and Double Twin.

KAWECO Comfort operating system

If the complexity of a tanker increases, the operating system must be adjusted accordingly. The KAWECO Comfort hydraulics if perfect for use in more complex systems. By using a Load-Sensing valve block, this can easily be extended with the required number of hydraulic functions. The benefits of a Load-Sensing system are self-evident: minimum pumping round of the hydraulic oil when the system is not used, an unlimited number of applicable hydraulic functions, complex sequential logic that are easy to realize and the possibility to operate multiple functions simultaneously. This operating system can be used on KAWECO PROFI I, and PROFI II among other products.

KAWECO Premium operation

When a KAWECO tanker has to be equipped with active dosing, the tank must become “intelligent”. This means that a computer is installed on the tanker that can actively respond to changing circumstances such as driving speed, slurry flow volume and operating width. For this system KAWECO offers a fully ISO-BUS system called KAWECO premium operation.

To operate the tanker, the driver uses a joystick with 24 functions and a 5,7″ Basic terminal with colour display. In this terminal, all the necessary settings can be changed and the buttons of the joystick can be adjusted to meet the driver’s needs. In addition to operating the tanker, the computer collects data that can easily be transferred to a PC. This data can be used the check per client exactly how much and for how long the machine had been used. In addition to many standard applications the computer can be extended with section closure, GPS and a navigation system for fields. It is also possible to opt for an 8″ or 11″ touch screen terminal. The benefits of these terminals especially include the ease of operation (Touch Screen) and the possibility to view multiple applications at once (cameras combined with GPS and tanker operation).

This operating system is used in all KAWECO PROFI III, DOUBLE TWIN shift and all Turbo and Swan neck tankers.

Do you have a question?

Fill in your details and we will contact you soon

When you use this form, you agree to the storage and processing of your data through this website. Data protection

Photo album

Gooseneck tandem and tridem

Gooseneck tandem and tridem

Specifications

| Net content [L] : | Tandem 24.500, 26.000, 28.000. Tridem 30.000, 32.000. Semi-trailer 30.000. |

|---|---|

| Undercarriage : | Integrated chassis with wheel arches Hydraulic axle suspension |

| Steering: | Hydraulic electric forced steering on the rear axle (and front axle in the case of tridem), via Mobil Elektronik |

| Hitch | KAWECO LIFTMAX PRO |

The gooseneck

Unique construction

The choice of pump systems

Hitch

The Semi-trailed tanker

Do you have a question about the gooseneneck?

Fill in your details and we will contact you as soon as possible.

Photo album

Gooseneck Double Twin Shift

Gooseneck Double Twin Shift

No other slurry tanker with a similar capacity is as soil-friendly as a KAWECO DOUBLE TWIN Shift. If paired with the efficiency of a CLAAS XERION and the agility of a gooseneck tanker you will have the perfect self-propelled machine. With a volume of 21,000 liters, KAWECO manufactures the largest single-axle tanker available on the market. Thanks to the undercarriage the soil pressure can be kept very low, despite the large volume of the tanker. KAWECO is the inventor of the DOUBLE TWIN SHIFT undercarriage which has 4 large tractor wheels in 1 single row. This gives the tanker the maneuverability of a single-axle slurry tanker, while it has the load capacity of a tandem axle tanker. This unique undercarriage means that injection requires a significantly lower soil pressure than a self-propelled machine. This means you can start your work sooner, and continue for longer, even in bad weather. Another major benefit is that your tractor can also be used for other work, as opposed to a self-propelled machine, which is not operational at least 6 months a year. KAWECO DOUBLE TWIN SHIFT, many wheels make light work!

The Double Twin shift undercarriage

The KAWECO Double Twin shift undercarriage has four large wheels in a single row. The wheels on the outside can be shifted outwards. This creates an even track of tanker and tractor wheels without having to go over the same track multiple times. Thanks to this unique system, the soil life suffers minimum damage, and the drainage of the soil is left intact. This results in fewer puddles in the field, no tracks, being able to start injecting sooner etc. The stable, extendible chassis profiles are equipped with synthetic strips, which makes the system very maintenance-friendly. The wheels have hydraulic suspension, which provide a well-balanced distribution of the weight over the 4 wheels. On the road, the hydraulic suspension provides comfortable and stable driving properties. All wheels are Air-braked for maximum safety.

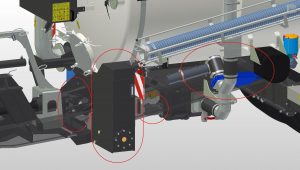

Pump and slurry piping

As in every KAWECO tanker the pump is the central part of the machine. The pump is hydraulically driven by means of the power hydraulics of the Xerion, which in turn are operated by the KAWECO computer. During filling this means that the power hydraulics are swiveled out to a maximum meaning that filling can take place at a minimum engine rpm. To increase the pump capacity, it is advised to install a maxifiller in the filling arm or front unit. This will not just increase the pump capacity, but also ensure less wear, thanks to a reduction of the negative pressure in the suction pipe. During the spreading of the slurry, the dosage is automatically adjusted to the driving speed thanks to the hydraulic adjustment of the pump speed. Thanks to 3-way valve at the back of the tanker, the slurry can circulated in the tanker when turning on the headland. This creates a faster availability of the slurry, and a better distribution during the first few meters of spreading.

Stonecatcher

To keep up the capacity of a pump, stones, feed residue and other contamination must be prevented from damaging the pump. KAWECO offers a Stonecatcher with sufficient volume to slow down the slurry flow for every pump type. This allows heavier objects to sink down to the bottom of the chamber. As an option, the Stonecatcher can be opened from the cabin, as a result of which these heavier objects can easily be removed. Feed residue will be shredded so that they cannot cause clogging. The cutting system uses a preloaded rotor with round mounted blades, that run across a hardox steel plate.

Filling arms

With various types of side and swivel arms and a complete Front-unit, KAWECO offers the perfect solution for every customer. Thanks to the standard 9,000 l/min pump, the filling arms always are at least 10″ in size. The standard filling arm offers the possibility to suck up slurry straight from deep manure pits. Optionally it can be fitted with a docking ball, which makes it easy to dock onto a nursetank. The TELE-arm can be hydraulically extended for 1.5 meters and it can swivel up to 170⁰. This means that docking onto a truck is made really easy. The KAWECO front unit has been especially developed for filling with a very high capacity, up to 12,000 l/min, and is installed in the front lift or is permanently installed in front of the XERION. This gives a perfect view on the slurry arm. A 10” maxi-filler and a 10” stone catcher with integrated cutter are standard equipment of the front unit. The complete suction piping is 10”.

Do you have a question about the Double Twin Shift gooseneck?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy

KAWECO DOUBLE TWIN SHIFT gooseneck options

Every KAWECO tank is standard equipped with a high-quality treatment. The inside is fitted with a two-component EPOXY resin. The outside is scoped and sprayed with two-component polyurethane lacquer. The standard color is KAWECO white with orange.

Two RAL colors are available as an option.

This treatment is many times more durable than a zinc layer and will retain its color even after years.

| • Required hydraulic volume: 55 l/min |

The maxi filler is recommended for thicker slurry or when the slurry has to be sucked out of a deeper cellar. The maxi filler also relieves the slurry pump, making it less vulnerable to wear and tear. In addition, the KAWECO maxi filler guarantees a faster loading process.

KAWECO DOUBLE TWIN SHIFT tires

Photo album

DOUBLE TWIN SHIFT

DOUBLE TWIN SHIFT Slurrytankers

The DOUBLE TWIN SHIFT slurry tanker is the most professional way of injecting slurry. The DOUBLE TWIN SHIFT slurry tankers make themselves indispensable thanks to their enormous volume, big filling capacity, maneuverability, and their well-developed undercarriage. With a volume of 12.000, 14,000 or 16,000 liters, KAWECO manufactures the largest single-axle tanker available in the market. Thanks to the undercarriage the soil pressure can be kept very low, despite the large volume of the tanker. KAWECO is the inventor of the DOUBLE TWIN SHIFT undercarriage which has 4 large tractor wheels in a single row. This gives the tanker the maneuverability of a single-axle slurry tanker, while it has the load capacity of a tandem axle tanker. This unique undercarriage means that you can inject with a significantly lower soil pressure than a self-propelled machine. This means you can start your work earlier in the year, and continue for a longer period than a self-propelled machine, even in bad weather. Another major benefit of the DOUBLE TWIN SHIFT is that your tractor can also be used for other activities, compared to a self-propelled machine, which is not operational for at least 6 months a year. KAWECO DOUBLE TWIN, many wheels make light work!

The DOUBLE TWIN SHIFT undercarriage

The KAWECO DOUBLE TWIN SHIFT undercarriage has four large wheels in a single row. The outer wheels can be shifted outwards. This creates an even track of the tanker and the tractor without driving over the same track multiple times. Thanks to this unique construction the soil life suffers minimum, and the drainage of the soil is kept optimal. This results in fewer puddles in the field, no tracks, being able to start injecting sooner in the year etc. The stable, extendible profiles are provided with synthetic sliding strips, which makes the system very user-friendly. The wheels have hydraulic suspension, which provides the perfect fit with the contours of the field, as well as a balanced distribution of the weight divided over the 4 wheels. On the road, the hydraulic suspension provides comfortable and stable driving properties. All wheels are Air-braked for maximum safety.

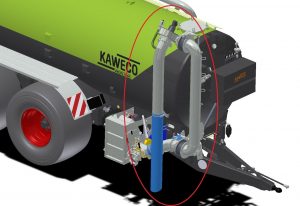

Slurry route and stonecatcher

Every tanker of slurry needs to be filled before spreading. Throughout the entire process, the filling capacity mostly depends on the slurry route, i.e. on the position of the pump, the pipes and the stonecatcher. The KAWECO pump is always placed in a central position of the machine, centralized underneath the tanker. This results in the shortest possible slurry route with fewer unnecessary bends and a better distribution of the weight. If you wish to use the maximum pump capacity, the pipes need to be adjusted. This means that we always use 8″ pipes to the suction side and maximum two 6″ to the pressure side. If the pump capacity increases the pipes will adjust with it. This means that a 9.000 l/min pump comes with 10″ suction pipes and 8″ pressing pipes.

Pumps and slurry piping with PTW tankers

Advantages of the PTW-tanker are: precise dosing and high filling capacity. The filling of the tank remains guaranteed, regardless of the thickness of the slurry. In addition, the filling capacity is better maintained with greater suction depth. Possible limitations of the PTW-tanker are: relatively high maintenance costs and more wear and tear. The weight of the machine is also increased by the required piping.

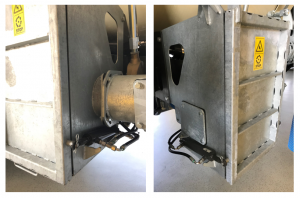

Hitch

All tankers from the DOUBLE TWIN SHIFT series are equipped with the heavy KAWECO Premium hitch. The hitch is fully mounted to the chassis, so that there will be no force on the tanker. The lifting cylinders are double-acting, which makes them adjustable both in terms of pressure and unloading, or even fully pressureless. Thanks to the standard operation of the hitch at the back of the tanker and the link hooks to the linkage, the mounting of an injector is very simple.

Pumps and filling arms

To unburden the driver, KAWECO offers a broad selection of filling arms for the DOUBLE TWIN Shift. Each filling arm is preferably placed to the right-hand side of the tanker, to create the shortest possible slurry route. In addition to the standard 8″ filling arm, with cylinder-operated pivot points, KAWECO also offers many crane and swivel arm options. A valve is mounted to vent the filling arm as soon as possible after the tanker has been filled. The slurry will flow back into the pit, with hardly any spilling. In most cases, KAWECO advises to install a maxifiller to be able to use maximum pump capacity. This maxifiller consists of a hydraulic driven vane wheel that presses the slurry into the suction pipe, which decreases the negative pressure on the pump side. The extra pump support offers many benefits that can be earned back fast. For example, the negative pressure is strongly reduced, meaning that the pump does not have to suck up the slurry as intensely. This will improve the machine’s lifespan, because parts that will wear, i.e. bearings, rotor and seals will not be used as intensely.

Slurry dosage

To guarantee perfect dosage, all DOUBLE TWIN SHIFT tankers are equipped with a BY-PASS dosing system. This system guarantees perfect dosing, by working with a flow meter. An upright pipe measures the amount of slurry pumped to the applicator. If this isn’t the right amount, the BY-PASS valve on the other side of the underlying Y-piece opens or closes. The position of this dosing valve is visible in the computer as a percentage. During the turning on the headland, the 3-way valve at the back of the tanker switches. When the next run has begun, the applicator can be filled with slurry straight away, meaning that slurry will flow from the outlets straight away. During the filling of the tank the dosing valve opens fully, meaning that at the pressing side of the pump an extension takes place to two 6″ pipes. This lowers the resistance on the pressing side, which increases the filling capacity.

KAWECO ISO-BUS controls

All DOUBLE TWIN SHIFT tankers are operated via KAWECO premium control. This control terminal offers many, conveniently arranged options. All panels are equipped with a multifunctional joystick with 24 functions and a 5,7″ Basic Terminal. As an option, we offer an 8″ or an 11″ Touch Terminal, and the PRO joystick.

KAWECO DOUBLE TWIN SHIFT options

Every KAWECO slurry tanker is standard equipped with a high-quality treatment. The inside is fitted with a two-component EPOXY resin. The outside is scoped and sprayed with two-component polyurethane lacquer. The standard color is KAWECO white with orange.

Two RAL colors are available as an option.

This treatment is many times more durable than a zinc layer and will retain its color even after years.

The KAWECO top pressure cylinder is designed for extra driving comfort and optimum weight distribution. The cylinder can push as well as pull and can be steplessly adjusted via the ISO-BUS. This allows extra pressure to be applied to the front axle of the tractor on the road or in the field for optimum weight distribution.

| • 10″ stonecatcher with integrated hydr. driven cutter |

| • Required hydraulic volume: 25 l / min |

| • Only possible with 9.000 l/min pump |

A larger pump of 9,000l/min also requires a larger flow of slurry. For maximum capacity, KAWECO builds the complete suction side out of 10″ pipes starting from a 9,000 l/min pump. Also the discharge side is increased from 6″ to 8″ pipes.

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic cylinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

The KAWECO filling-arm saves you valuable time and makes filling easier. Optionally, the filling arm can be equipped with a maxi-filler for optimum capacity.

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

The KAWECO suction arm saves you valuable time and makes filling easier. The PRO version is equipped with a hydraulic spindle motor for a larger swiveling range. Optionally, the filling arm can be equipped with a maxi-filler for optimum capacity.

| • One pivot point, actuated by a hydraulic cylinder |

| • Std. 8″ Maxi Filler |

| • Std. 8″ slide under the Maxi filler |

| • Mirrors mounted on the left and right of the front unit for road safety |

| • Std. Lighting for front unit |

With the KAWECO FRONT-UNIT it is easy to dock to a nursetank. With the arm in front of the cabin you have perfect visibility. Also, the applicatorboom can always be folded out because you don’t have to stand sideways along the nursetank.

| • Required hydraulic volume: 45 l / min |

The maxi filler is recommended for thicker slurry or when the slurry has to be sucked out of a deeper cellar. The maxi filler also relieves the slurry pump, making it less vulnerable to wear and tear. In addition, the KAWECO maxi filler guarantees a faster loading process.

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

The Hydro Dynamic makes it possible to spread slurry with completely variable rates. The dosage is regulated by the rotations of the slurry pump. With this system, the application rate can be quickly adjusted when, for example, working with a section-control.

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

The Hydro Dynamic makes it possible to spread slurry with completely variable rates. The dosage is regulated by the rotations of the slurry pump. With this system, the application rate can be quickly adjusted when, for example, working with a section-control.

KAWECO DOUBLE TWIN SHIFT Tires

Do you have a question about the Double Twin Shift?

Fill in your details and we will contact you as soon as possible.

By using this form, you agree to the storage and processing of your data by this website. Privacy & Cookie policy

Photo album

DOUBLE TWIN

DOUBLE TWIN

Often copied but never equaled is the KAWECO DOUBLE TWIN undercarriage. With over 15 year of experience, KAWECO is market leader in spreading slurry in a soil-friendly manner. DOUBLE TWIN means 4 tractor wheels in a row. The benefits are obvious: less damage to the soil while applicating and easy turning on the headland. The 4 large tractor wheels provide an enormous surface and lower tire pressure which means there is less pressure on the soil. Because the tires are relatively narrow, turning on the headland is easier, and narrow turns can be made without damaging the turf.

KAWECO DOUBLE TWIN, many tires make light work!

The DOUBLE TWIN undercarriage

The KAWECO DOUBLE TWIN undercarriage consists of 2 pendulum elements, both with 2 axle housings. The pendulum elements provide a perfect soil adjustment and ensure that the load is distributed evenly during transport. Integrating the DOUBLE TWIN undercarriage in the chassis of the tanker results in a compact and strong construction that in terms of weight, is equal of even lighter than our closest competitors.

Hitch construction

The entire DOUBLE TWIN series is equipped with the heavy KAWECO Premium linkage. The hitch is fully mounted to the chassis, so that there will be no traction on the tanker. The lifting cylinders are double-acting, which makes them adjustable both in terms of pressure and unloading, or fully pressureless. Thanks to the controls of the hitch at the back of the tanker (Optional) and the linkage hooks, mounting a slurry injector is very simple.

Pumps

All KAWECO DOUBLE TWIN tankers come with high-grade BP vacuum pumps by default. The standard pumps have a compressor capacity of 13,500 L/min. This capacity is achievable because of the rotor with 4 slanted rotor blades. The blades are cooled and lubricated by a drip oil pump. To further improve the cooling (keeping the capacity at the desired level) the pump is equipped with standard direct air injection. If the machine comes to a standstill, a special valve in the pump will preserve the vacuum.

If you work with a field edge container, for instance, and the pump is continuously running at full capacity, you can opt for a water-cooled vacuum pump. The cooling water will be pumped into a separate compartment of the tanker through a separate water pump.

Pumps and slurry piping at VC tankers

Advantages of the vacuum tank include: little wear and tear, low maintenance costs and low own weight. Disadvantages are: the dosage, the capacity during filling and unloading. Furthermore, during filling, the slurry is, as it were, pulled apart by the air displacement. As a result, the tank is never completely filled.

Operation

The functions of the tanker are operated by means of the tractor’s valves. To simplify the process, the hitch and the valve at the back of the tanker are combined by means of a sequential switching valve. If, however, multiple, very demanding functions are installed, the tanker is equipped with the KAWECO Comfort operating system. To operate the valves, the joystickbox can be used, which is easy to install in the tractor. For tankers with speed dependent dosage, the KAWECO Premium ISO-BUS operating system can be used. The tanker will then be operated by means of a joystick with 24 functions, and a 5,7″ Basic terminal with color display.

KAWECO DOUBLE TWIN OPTIONS

The PROFI II can be equipped with a suspended drawbar. This enhances the driving comfort. Especially when driving a lot on the road. The height of the tank can also be easily adjusted.

The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s). With a PTW model, a Stonecatcher with hydraulic cutting work is almost always mounted.

The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s). With a PTW model, a Stonecatcher with hydraulic cutting work is almost always mounted.

| • Filling arm right side |

| • Pivot point under controlled by a hydraulic cilinder |

| • Pivot point above controlled by a hydraulic cilinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

The KAWECO filling-arm saves you valuable time and makes filling easier.

| • Filling arm right side |

| • Pivot point under controlled by a hydraulic cilinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

The KAWECO suction arm saves you valuable time and makes filling easier. The PRO version is equipped with a hydraulic spindle motor for a larger swivelling range.

| • Required hydraulic volume: 45 l / min |

The maxi filler is recommended for thicker slurry or when the slurry has to be sucked out of a deeper cellar. The maxi filler also relieves the slurry pump, making it less vulnerable to wear and tear. In addition, the KAWECO maxi filler guarantees a faster loading process.

This guillotine valve ensures that the filling-arm leaks less.

| • CAT II / III on CAT II width 870 mm |

| • Max. lifting capacity 3.200 kg, arable land injector 3.000 kg |

| • Sequence linking single-acting lifting cylinder |

| • 1 x DA tractor valve for single acting hitch cilinder, valve and distributor (not reversible) |

| • 1 x DA tractor valve for folding in and out fertilizer |

• Control: 1 DA tractor can be used for 5 different functions. The Easy-Go is the easiest option for joystick control. When choosing a control system, it is important to consider how many functions the tanker needs. Up to 5 functions can be operated with an Easy-Go system. When a lot of oil is required or a applicator needs to be controlled, you can choose for a Load-Sensing control.

| • KAWECO multifunctional joystick with 24 functions |

| • KAWECO BASIC Terminal |

| • Operation of automatic dosage control |

The KAWECO ISO-BUS control is a Load-Sensing control system with which all tank functions can be controlled. The system also directly takes care of the oil quantity. A target value is entered after which the application rate is regulated by the By-Pass valve. The amount of slurry that goes to the injector is measured with a flow meter.

KAWECO DOUBLE TWIN tires

Do you have a question?

Fill in your details and we will contact you as soon as possible.

When you use this form, you agree to the storage and processing of your data through this website. Data protection