PROFI III-Series

PROFI III-Serie Slurrytanker

Specifications

| Net contents [L]: | Tandem: 16,300, 18,500, 20,260, 23,200 Tridem 23,000, 25,000, 28.000, 30,000, 32,000 |

|---|---|

| Undercarriage: | Hydraulic pendulum suspension, come with 2 large accumulators for optimum suspension when empty and full |

| Steering system: | Tandem up to 20,000 = hydraulic forced steering by hydraulic cylinder on the left-hand side of the drawbar. Tandem 23,200 = Forced steering through mobile Elektronik control system. Tridem = up to 25,000 front and rear axle hydraulic forced steering. Tridem From 28,000 = hydraulic forced steering through mobile Elektronik control system. |

| Axle base [mm]: | 1.810 |

Undercarriage and tanker construction

Hitch

Undercarriage

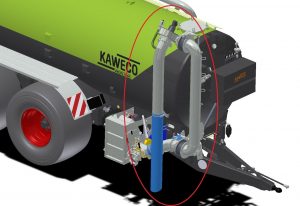

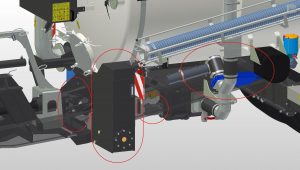

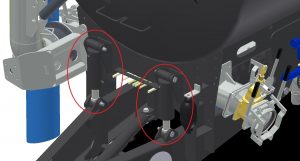

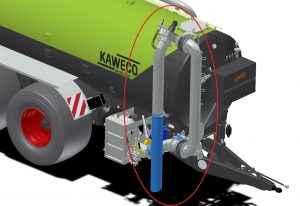

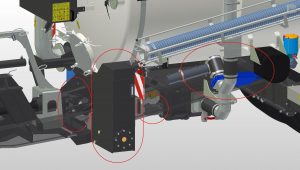

Pump and slurry piping PTW tanker

Slurry route and stonecatcher

Pumps and filling arms

KAWECO ISO-BUS control

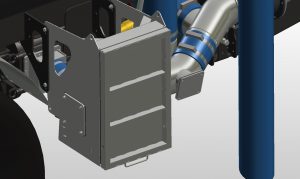

Weighing and sampling

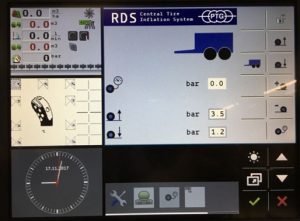

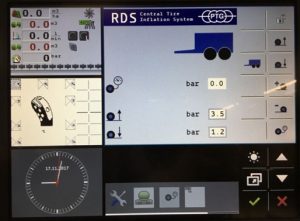

Tyres, wheels and soil pressure

Options for Profi III

KAWECO PROFI III standard equipment

| > Fixed lower links CAT III (width of 1,010mm) |

| > Mechanical adjustable toplink CAT III |

| > Double working lifting cylinder with ground pressure regulation system |

| > Lifting cylinder with damping |

| > Maximum lifting capacity 4.000 kg (depending on tank and injector version) |

| > 2 buttons on rear side of the tanker to lower or to lift the hitch |

| > 7-pin plug for lighting of applicator |

| • KAWECO Maxi Cut Premium 8″ | |

|

| KAWECO ISOBUS Control including: | |||

|

KAWECO PROFI III options

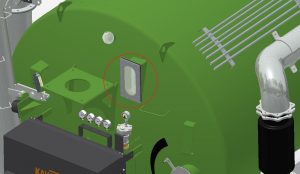

| • 10″ stonecatcher with integrated hydr. driven cutter |

| • Required hydraulic volume: 25 l / min |

| • Only possible with 9.000 l/min pump |

| • For docking station located at the ground (slide valve mounted at stonecatcher) |

| • First pivot point controlled by a hydraulic cylinder |

| • Std. With slide valve and vent valve mounted at the end of the arm |

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic cylinder |

| • Std. With valve between filling arm and stonecatcher |

| • Max working height +/- 3.80 meters. Not suitable for docking. |

| • Filling arm right side |

| • First pivot point controlled by a hydraulic cylinder |

| • Second pivot point controlled by a hydraulic spindle motor |

| • Std. With valve between filling arm and stonecatcher |

| • One pivot point, actuated by a hydraulic cylinder |

| • Std. 8″ Maxi Filler |

| • Std. 8″ slide under the Maxi filler |

| • Mirrors mounted on the left and right of the front unit for road safety |

| • Std. Lighting for front unit |

| • Required hydraulic volume: 45 l / min |

| • Closed Load-Sensing system for driving (only) the manure pump |

| • Including ECO-Motion transmission with 2 gears + By-pass valve in tank |

| • Dosage by rpm sensor on the pump instead of flow meter |

| • All other functions on the tank are operated by Load-Sensing of tanker |

KAWECO PROFI III Tires

Do you have a question about the PROFI III?

Fill in your details and we will contact you as soon as possible.

Photo album

PROFI II-Series

PROFI II-Series slurrytanker

specifications

| Net contents [L]: | Single axle 8,200, 10,500 and 12,000. Tandem 11,500, 12,500, 14,000, 16,200, 17,900, 19,900 Tridem 22,900 |

|---|---|

| Undercarriage: | Roll-over Buggy up to 18.000 L, Hydraulic axle suspension from 20,000 L |

| Control system: | Rear axles lagging control up to 18,000 L, rigid control from 20,000 L |

| Axle base [mm]: | 1,700 to 14,000 L, 1,810 from 16,200 L |

The PROFI II construction method

Unique drawbar

Modular built

Pump and slurry piping VC tanker

Pump and slurry piping PTW tanker

Well developed slurry route

KAWECO LIFTMAX PREMIUM Hitch

KAWECO PROFI II standard equipment

KAWECO PROFI II OPTIONS

- Lower pivot point controlled by cylinder

- Upper pivot point controlled by cylinder

- Standard: slider between suction arm and cutting device

- Standard: pressure relief valve to vent the filling arm immediately after filling

- Lower pivot point controlled by cylinder

- Upper pivot point controlled by spindle motor

- Standard: slider between filling arm and cutting device

- Standard: pressure relief valve to vent the filling arm immediately after filling.

- A pivot point (below) controlled by cylinder

- Standard: pressure relief valve in end andock arm

- Hydraulic power required: 45 l/min

- CAT II/III catch hook on CAT II width 870 mm

- Maximum lifting capacity greenland fertilizer: 3,250 kg, arable fertilizer: 3,000 kg. Measured one meter behind the balls.

- Automatic lubrication on the injector is possible at extra cost and is not included in the standard calculation.

KAWECO PROFI II Tires

Do you have a question about the PROFI II?

Fill in your details and we will contact you as soon as possible.

Photo album

PROFI I-Series

PROFI I-Series slurrytanker

The KAWECO PROFI I slurry tankers stand out because of their light, yet stable construction. The tankers can easily be fitted with a dribble bar applicator with a working width up to 15m. Thanks to the modular set-up the tankers are easy to adjust according to your needs.

Specifications

| Net contents [L]: | Tandem 10.000(ESP), 12.500(ESP), 14.400, 16.200, 17.600 and 20.000 |

|---|---|

| Undercarriage: | Roll-over Buggy |

| Control system: | Rear axle lagging control (rigid control is optional) |

| Axle base [mm]: | 14,400 L = 1,700 mm. 16,200 & 17,600 = 1,810 mm. |

Be ready for the future

All PROFI I slurry tankers are mechanically able to fit an additional dribble bar applicator. This means that you are always ready for the future, even with changing legislations. Thanks to the stable construction of the tanker, the applicator (trailing shoe or dribble bar) can be upgraded to a maximum working width of 15m. KAWECO has strong relationships with several suppliers of premium applicators.

Tanker and chassis

Integrating the undercarriage in the tanker decreases the tare weight while at the same it increases the stability of the machine. Thanks to the double wheel arches, the axles can be mounted on top of the spring assembly of the buggy. This results in a low center of gravity and a maximum height of 3.25m (with a tire size of 750/60R30.5). For optimum protection the tanker undergoes a special treatment. The tanker gets covered with a zinc layer (galvanization). To be able to spray the zinc layer properly, it gets thoroughly sanded first. This treatment results in a tanker protection that will be corrosion-proof for years and that is easy to clean. An option is to spray the tanker in two different colors. The inside of the tanker is treated with a special epoxy-resin. Thanks to its thickness and flexibility the tanker is better able to withstand any circumstances.

Drawbar

The very narrow drawbar makes a PROFI I tanker very easy to maneuver. The tankers standardly comes with a rear free steering axle. When the tanker is optionally fitted with forced steering, the steering cylinder is placed on the left, next to the drawbar. Because of the crash protection the maximum steering angle is limited. The system is installed to protect the steering cylinder. The coupling height can be changed with the extra holes in the drawbar. As an option, the drawbar can be fitted with hydraulic drawbar suspension, which results in greater comfort.

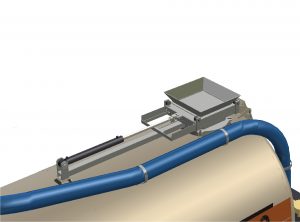

Pumps and slurry piping with PTW tankers

The PROFI I tankers are available as vacuum (VC version), rotary lobe pump (PTW version) and eccentric screw pump (ESP version) tankers. By default, the PTW tankers are delivered with a Vogelsang VX186-184Q pump. This pump delivers 4.266 l/min at 600rpm. Thanks to a unique slanted plate in front of the entry of the pump any contamination will be caught in between the two rotors. This results in less damage to the lobes and the casing of the pump. Click here to see a video from Vogelsang Injection System. As an option we have a Vogelsang VX186-260Q pump with a capacity of 6,000l/min at 600rpm available. To guarantee a high degree of operational reliability and high pump capacity the PTW models come with a standard special pump chamber. This is mounted before the pump and guarantees a minimum amount of slurry in the intake piping of the pump. Thanks to the continuous filling of the pump it can never run dry and it will reach a negative pressure a lot faster. This will ultimately increase the capacity of the pump and reduce wear.

Advantages of the PTW-tanker are: precise dosing and high filling capacity. The filling of the tank remains guaranteed, regardless of the thickness of the slurry. In addition, the filling capacity is better maintained with greater suction depth. Possible limitations of the PTW-tanker are: relatively high maintenance costs and more wear and tear. The weight of the machine is also increased by the required piping.

Pumps and slurry piping at VC tankers

All PROFI I vacuum tanks are equipped as standard with very high quality BP vacuum pumps. The standard pumps have a compressor capacity of no less than 13,500 L/min. This capacity is realized by a rotor with 4 inclined rotor blades. The blades are cooled and lubricated by an oil drip pump. In order to further improve the cooling and to keep the capacity at the same level during the work, the pumps are standard equipped with direct air injection. When the pump is at a standstill, a special valve ensures that the vacuum is maintained.

Advantages of the vacuum tank include: little wear and tear, low maintenance costs and low own weight. Disadvantages are: the dosage, the capacity during filling and unloading. Furthermore, during filling, the slurry is, as it were, pulled apart by the air displacement. As a result, the tank is never completely filled.

Click here for a video of the Battioni Pagani Ballast pumps.

Pumps and slurry piping at ESP tankers

The PROFI I ESP tanks are standard equipped with high quality WANGEN worm pumps, with a capacity of 4,000 l/min at 540 rpm. Larger worm pumps are optionally available. The WANGEN pump has a compact design and is built lengthwise underneath the tank. In this way, the slurry route consists of as few bends as possible. Just like the PTW version, the ESP version is equipped with a three-way valve for switching between filling and emptying.

The advantages of the worm pump are: the large passage of unwanted parts in the slurry and the low maintenance costs.

KAWECO PROFI I standard equipment

Standard LED road lights.

KAWECO PROFI I OPTIONS

Every KAWECO tank is standard equipped with a high-quality treatment. The inside is fitted with a two-component EPOXY resin. The outside is scoped and sprayed with two-component polyurethane lacquer. The standard color is KAWECO white with orange.

Two RAL colors are available as an option.

This treatment is many times more durable than a zinc layer and will retain its color even after years.

Two-compartment system, to maintain drawbar pressure during application of slurry (only possible with PTW/ESP). This system ensures that optimum pressure is maintained on the drawbar during application of slurry by leaving slurry in the front chamber.

Maxi filler 8 “mounted centrally under the tanker. With the KAWECO maxi filler you can fill from both sides with a hand valve. The maxi filler is recommended for thicker slurry or when the slurry has to be drawn from a deeper cellar. The maxi filler also relieves the slurry pump, making it less susceptible to wear and tear.

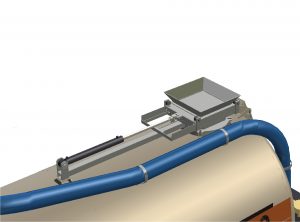

Stonecatcher 8 “without cutting unit. The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s).

Stonecatcher 8 “with hydraulically driven cutting unit (25 l / min). The Stone Catcher is recommended when there are often objects in the slurry such as stones. To prevent damage to the pump or distributors of the applicator, it is in many cases advisable to build a stone catcher. Even in the case of a vacuum tank, this prevents blockages in the distributor(s).

Docking arm 8″ right with valve and hydraulic slewing ring.

The suction arm relieves you of daily work and allows you to fill up quickly and easily with a docking station. If there is a wish for a larger suction arm, choose the PROFI II.

Optionally in combination with a maxi filler for optimal capacity.

Control: 1 DA tractor can be used for 5 different functions. The Easy-Go is the easiest option for joystick control. When choosing a control system, it is important to consider how many functions the tanker needs. Up to 5 functions can be operated with an Easy-Go system. When a lot of oil is required or a applicator needs to be controlled, you can choose for a Load-Sensing control.

The KAWCO Easy Bus is the simple version of the KAWECO ISOBUS-Control. The Easy Bus does not come with a terminal as standard because operation is possible via the tractor terminal. The control functions in the same way as the Load-Sensing control box but via the tractor terminal. The advantage of this ISOBUS operation is that the system can be used with various tractor terminals as well as external terminals. The Easy Bus can be expanded with a flow meter and manual dosage (for PROFI II).

The Load-Sensing adjusts the oil flow to the demand of the tank, so that oil is not pumped around unnecessarily. With Load-Sensing many functions are easy to operate. KAWECO Load sensing valve block with filter and assembly board with control box.

KAWECO PROFI I Tires

Alliance 750/45R 26.5 885 ø1360 (Without Wheel arches)

Alliance 750/60R 30.5 885 ø1680 (With Wheel arches)

Alliance 650/60R 26.5 380 ø1450 (Without Wheel arches)

Alliance 750/45R 26.5 380 ø1350 (Without Wheel arches)

Alliance 650/65R 30.5 A380 (With Wheel arches)

Alliance 750/60R 30.5 A380 ø1680 (With Wheel arches)

Alliance 750/60R 30.5 A390 ø1670 (Met wielkasten)

Trelleborg 650/65R 30.5 Twin Radial (With Wheel arches)

Trelleborg 750/60R 30.5 Twin Radial ø1670 (WithWheel arches)

Do you have a question?

Fill in your details and we will contact you performed ASAP.

When you use this form, you agree to the storage and processing of your data through this website. Data protection