RADIUM 260

The KAWECO RADIUM 260 can house a whopping 52m3 of silage. This tridem silage wagon is the flagship and largest silage wagon available today. It comes with hydraulic axle suspension, drawbar suspension and hydraulic forced steering, which make this wagon perfectly controllable. The RADIUM was updated to the 2.0 version in 2019. The most important changes are the design, the total height below 4 meters including R30.5 tires, and the faster unloading.

Let yourself be amazed by the high unloading speed!

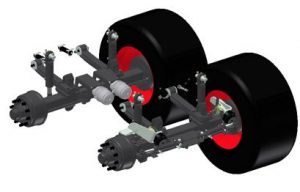

Undercarriage

The enormous volume of a RADIUM 260 places a considerable burden on the undercarriage. To manage this, the RADIUM 260 is equipped with hydraulic axle suspension and hydraulic forced steering. The hydraulic axle suspension is fitted with a load-dependent two-chamber nitrogen suspension system. This suspension provides an optimum balance between load, suspension and speed, which creates ideal driving properties. The broad axle base, which is standard, allows for mounting the tires up to a height of 1500 mm (R30,5) without exceeding 4 meters (Including cover system).

The superstructure

The RADIUM was the first silage wagon with a conical superstructure: the rear is 5 cm wider than the front. This guarantees a good unloading process, no matter which silage product has to be unloaded. The conveyor floor is galvanized for the longest possible life-span. By bolting on the side posts we create a very lightweight yet stable side wall which can be easily be renewed.

Front wall

The front wall of the silage has been made from a grid plate, so that driver has a perfect view of the loading process of the wagon. The top part of the front wall can be lowered hydraulically, which makes the loading easier during the mowing of a new corn field. An alternative solution for the fast and easy mowing of a new corn field is the tipping RADIUM series; this version makes it easy to follow the forage harvester backwards.

Tailgate

The tailgate has mechanical transport protection to ensure safe transport. Hydraulic cylinders first lift the tailgate vertically so that it is released, after which it can be opened. The new RADIUM has a completely closed tailgate to make sure no silage is lost along the way.

Conveyor chains

All RADIUM silage wagons are equipped with 4 strong and durable chains that are driven by a double gearbox. The heavy chains and double drive make for easy, fast and reliable unloading. The no-maintenance conveyor chain is placed between the chassis and the superstructure, so that it is protected optimally. The new RADIUM 2.0 unloads considerably faster than its predecessor, so it was decided to work with a different type of chain.

Wagons without silage beaters have a hydraulic drive, wagons with silage beaters are equipped with a mechanical drive. The silage beaters are also mechanically driven and they are linked through a chain transmission. Automatic chain tensioners ensure the perfect chain tension at all times.

Silage beaters

The RADIUM silage wagons can also be fitted with silage beaters, which ensure an equal distribution of the silage product over your silo. Thanks to the equal distribution over the complete length of your silo, you will need less time to level the silo with the wheel loader/tractor. This results in a higher silage quality and a higher capacity of your harvesting team.

KAWECO RADIUM OPTIONS

Do you have a question about the RADIUM?

Fill in your details and we will contact you as soon as possible.